A Helping Hand for the Gym

In collaboration with Operation Namaste, I collaboratively prototyped a portable 3D printer that folds into a briefcase. The work culminated in bringing the prototype to Camp No Limits at Quinnipiac University in July 2019, where I spent a long weekend working with prosthetists and a congenital amputee to design and print her a hand device for working out in the gym. Here are some pictures showing the process:

Day 1: July 12

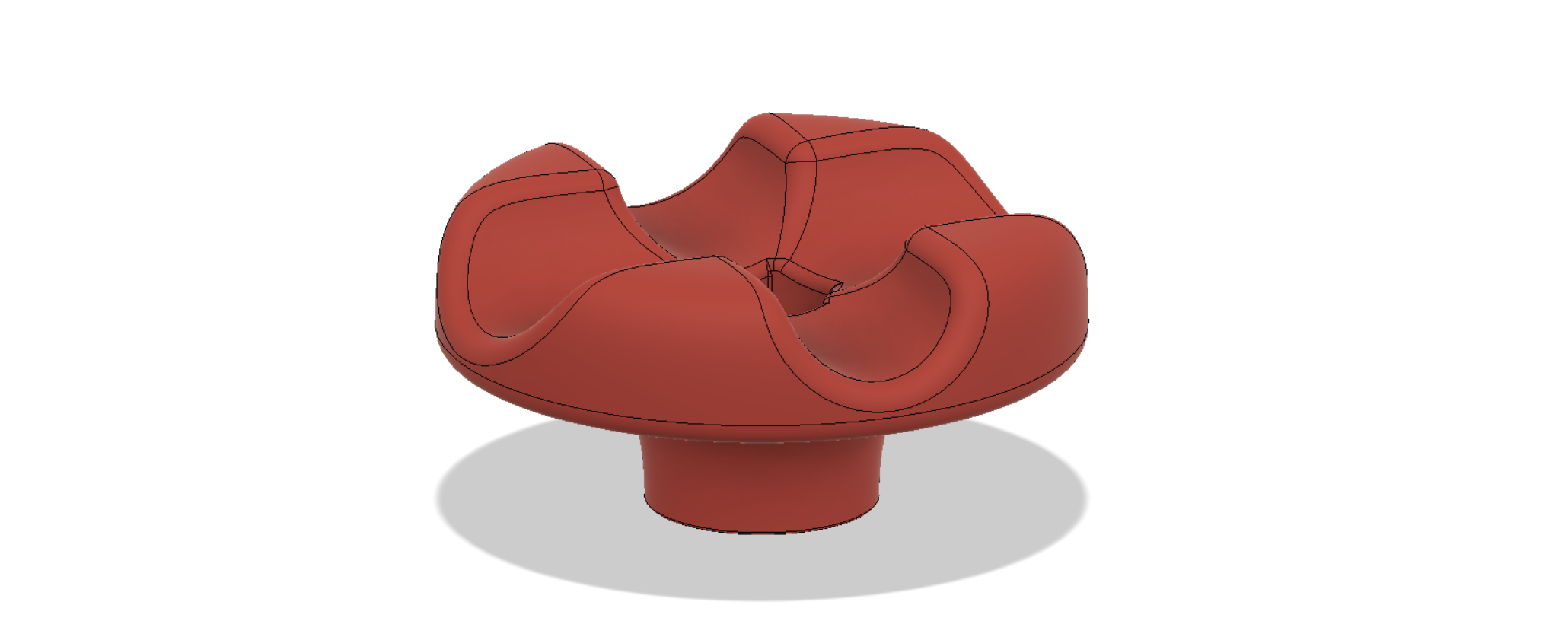

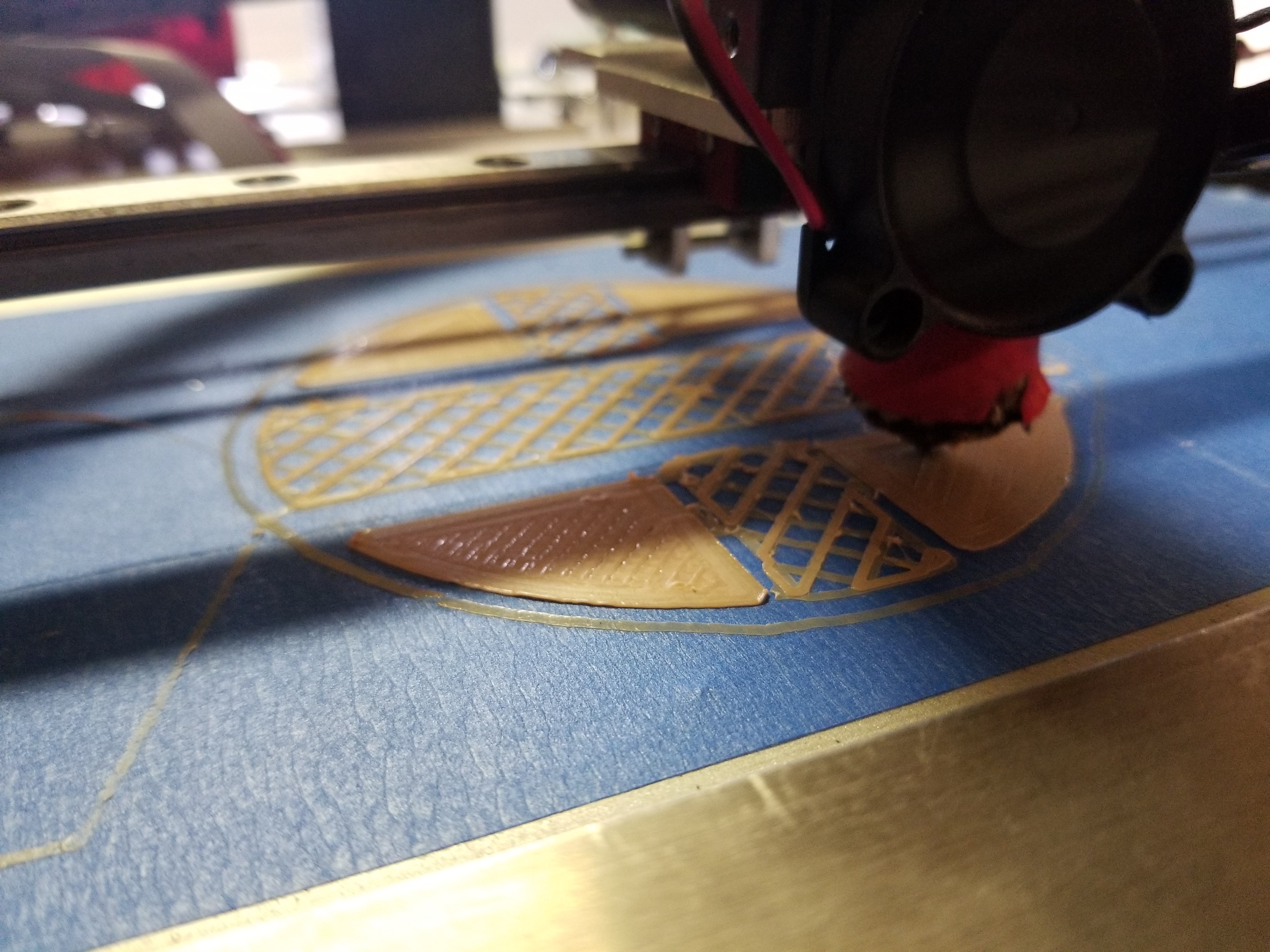

The initial CAD model. Two different-diameter notches on the distal end allow for easy, no-slip support when pushing against a bar. The mushroom shape allows for hooking around bars and pulling on them.

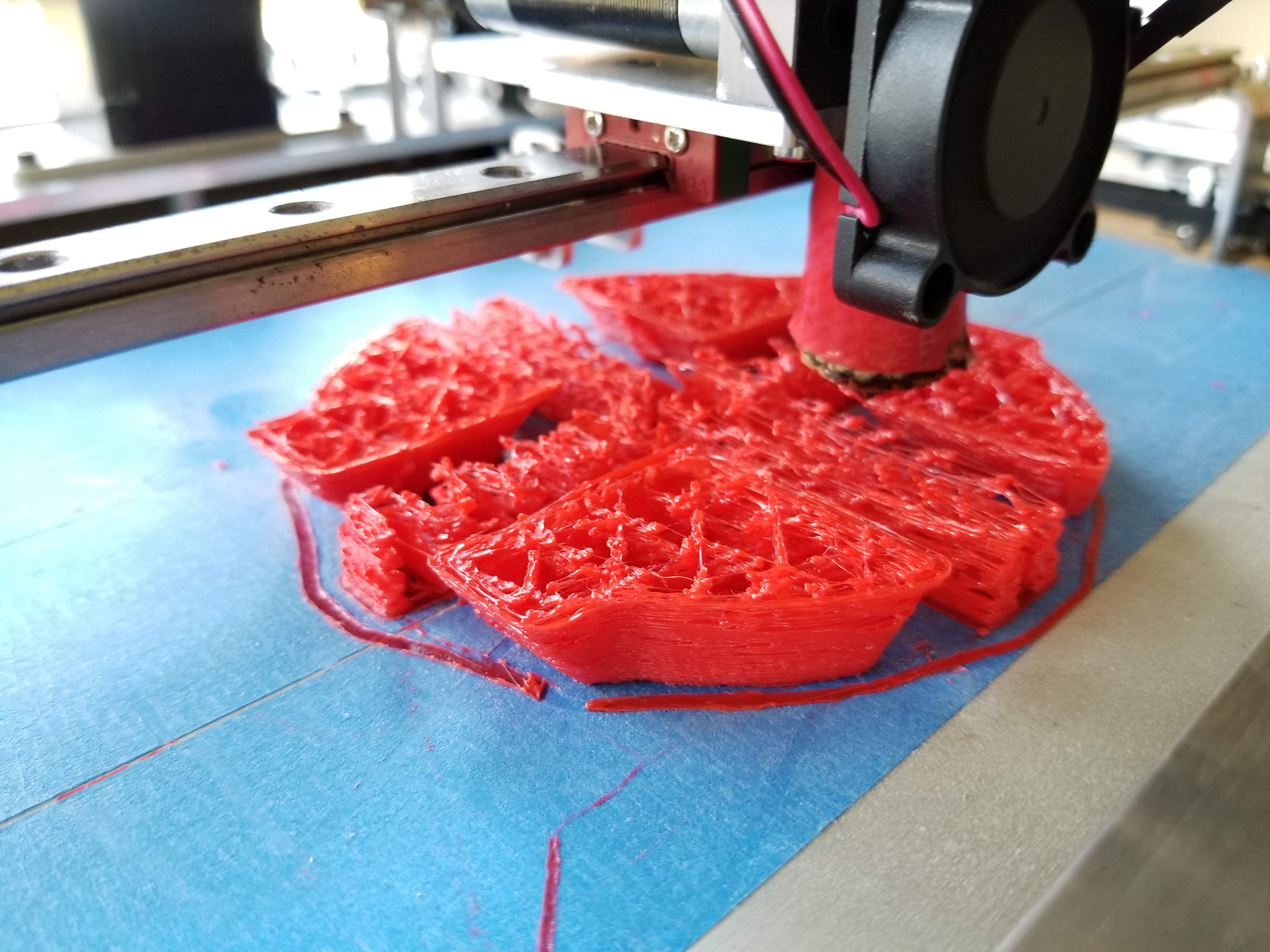

The first printed version. The patient liked how the notches performed, but the mushroom shape wasn't secure enough to help her lift weights.

Day 2: July 13

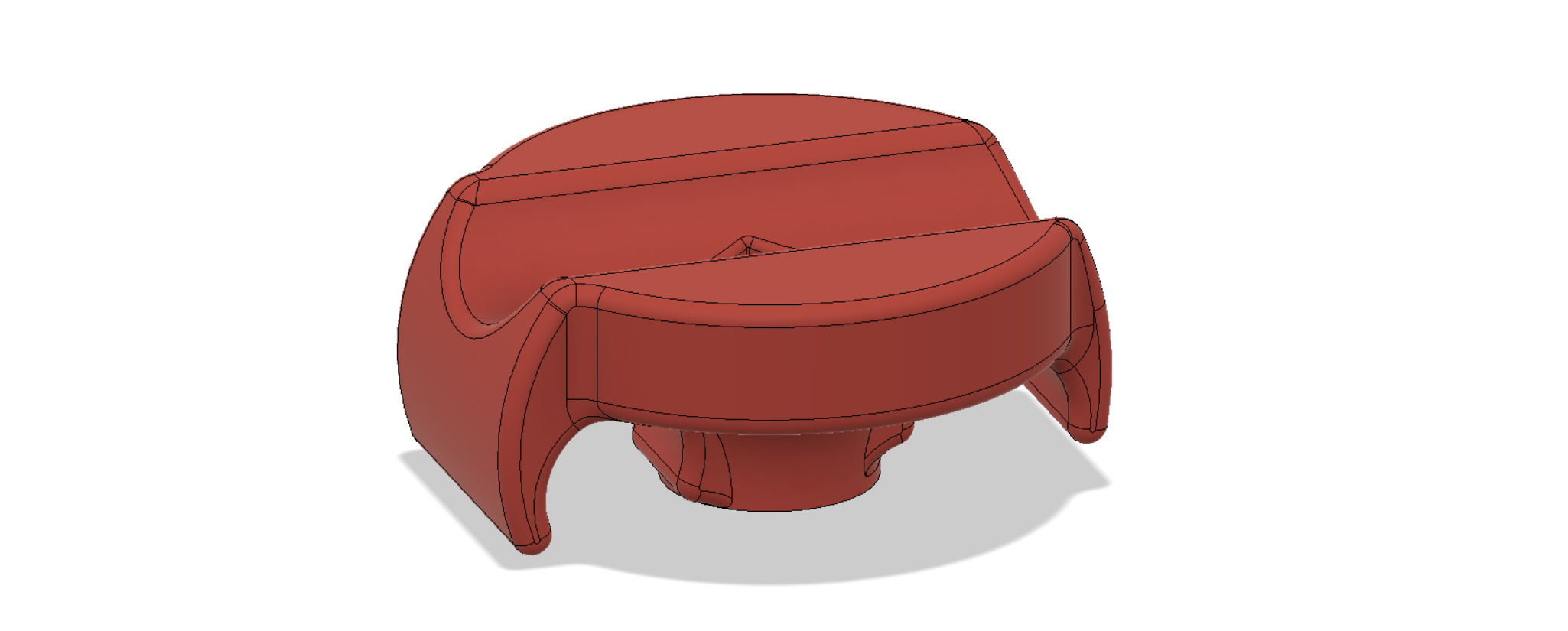

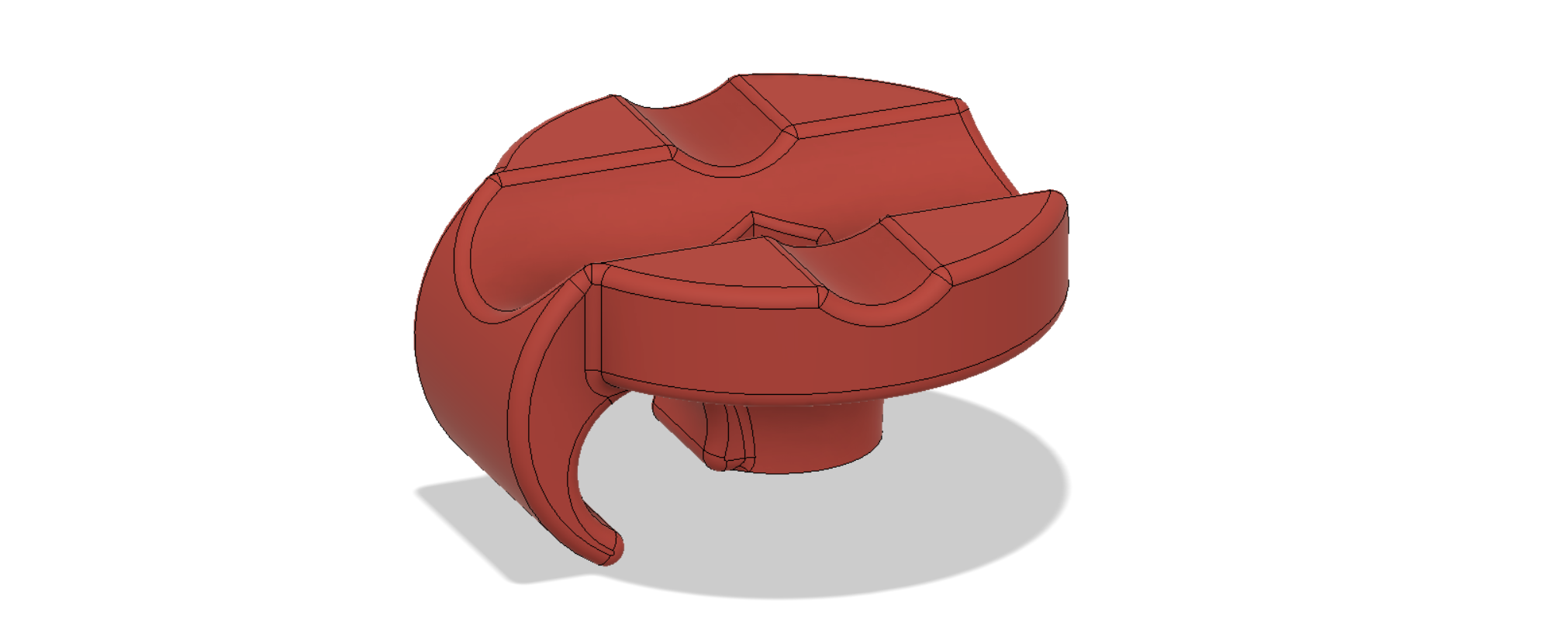

One of two second-iteration CAD models. A notch is removed to increase stiffness, and two hook features (of different diameters) are present. These provide a more secure way to pull on or lift bars.

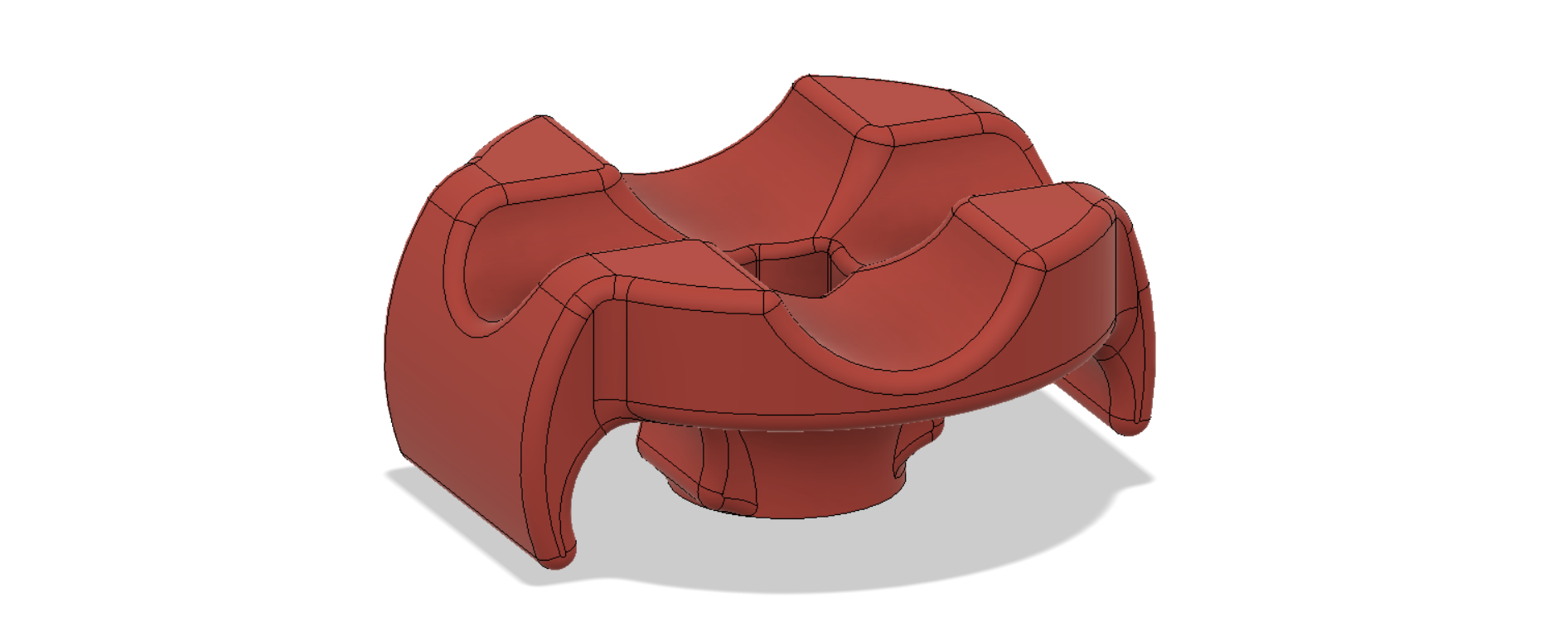

The other second-iteration CAD model. Here, both notches remain. The hook features are the same as the single-notch concept.

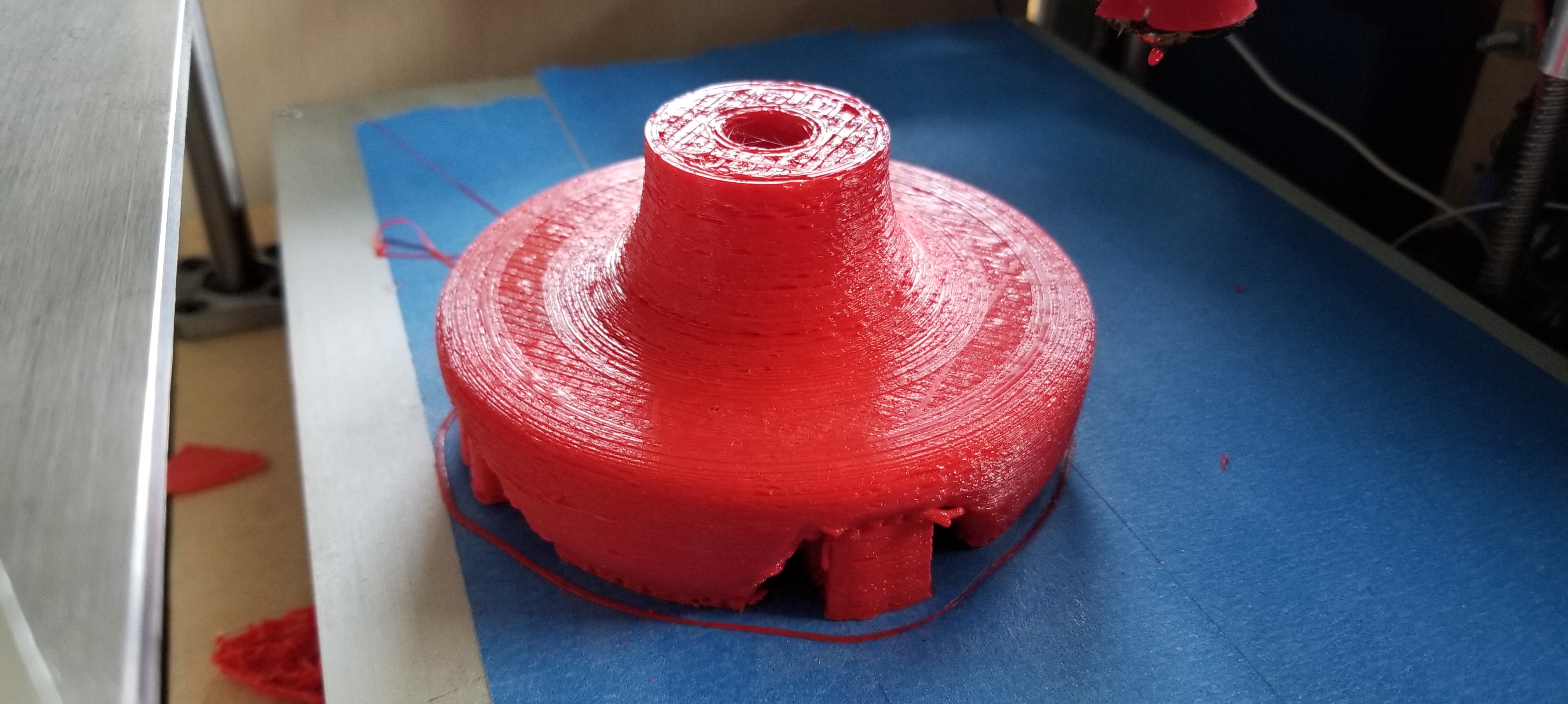

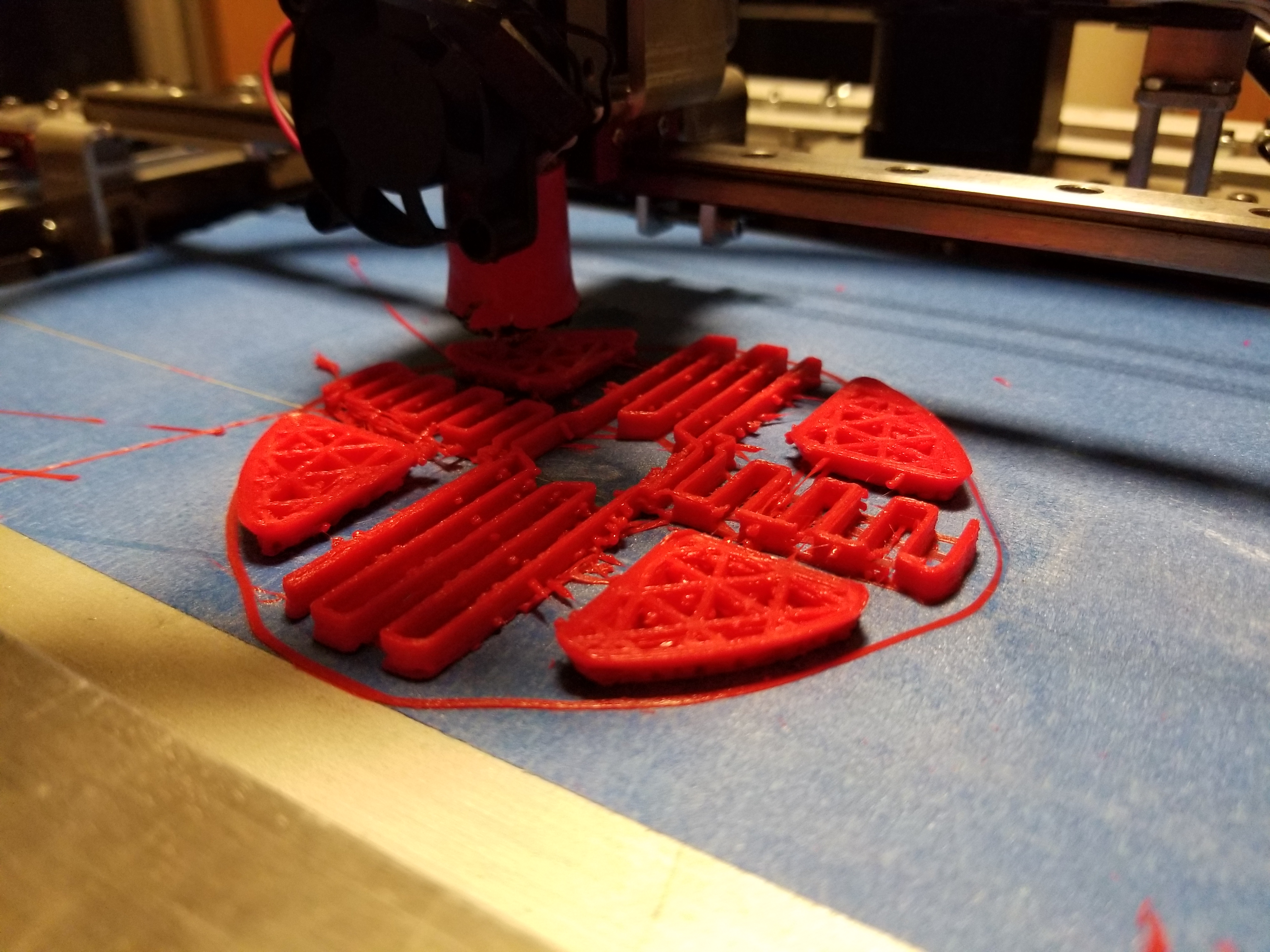

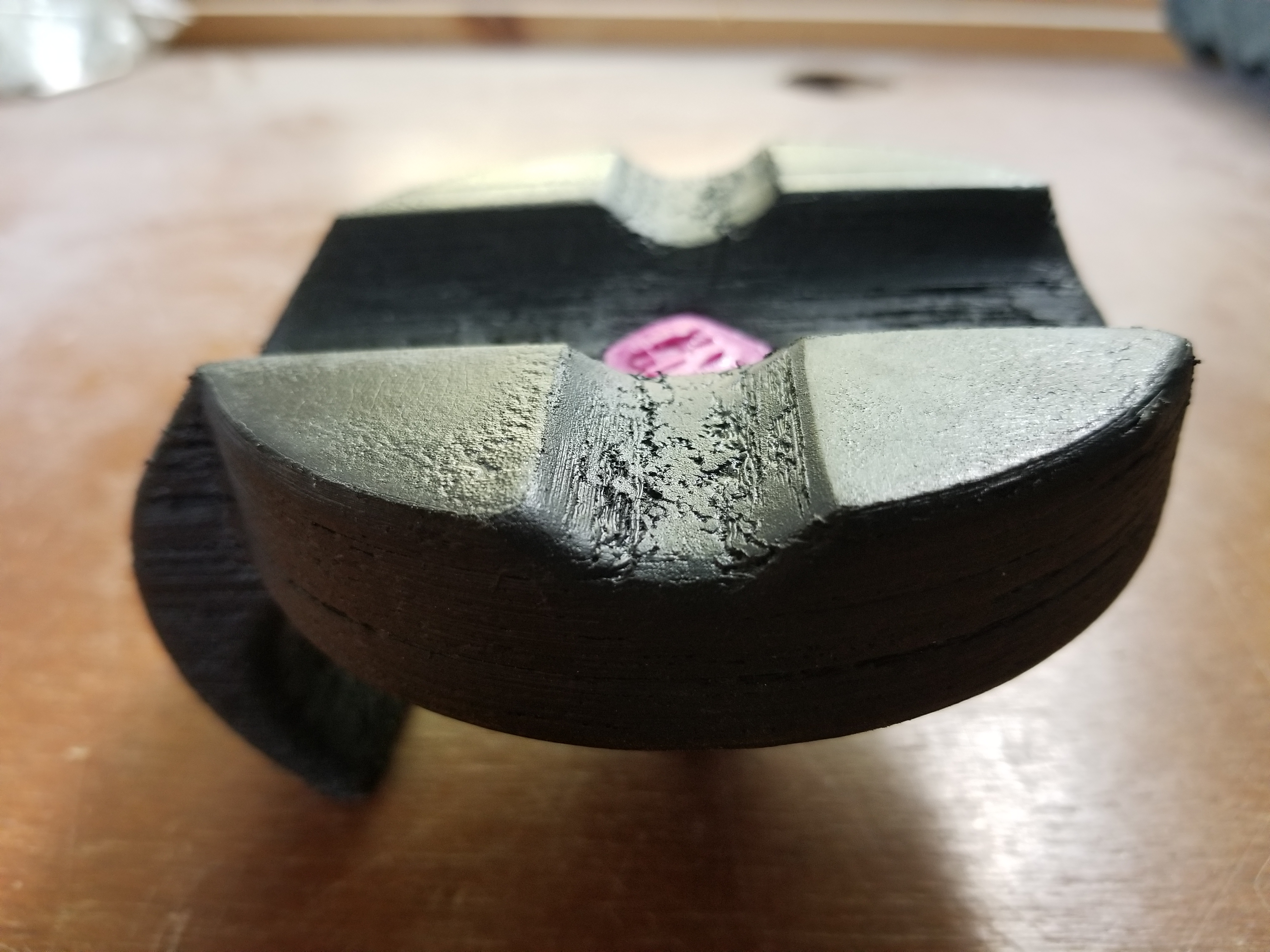

Printing the two-notch, two-hook model. Extrusion was somewhat inconsistent with the TPU filament we used.

Day 3: July 14

After the patient saw the two second-iteration concepts and tried out the print of the two-notch version, she noted that having two hooks was annoying. The mushroom shape was useful for smaller pulling tasks, but that usefulness decreased significantly when an extra clip-hook feature got in the way. She also said she would prefer a slightly stiffer feel when pulling on a bar.

The final concept. This version reduces the size of one notch to increase stiffness in that direction, and it only includes one clip-hook feature, leaving room to use the mushroom shape for smaller tasks.

Printing the final concept. This specific print didn't finish before Camp No Limits ended, so it had to be scrapped.

After Camp No Limits

Printing the final concept, take two (using a better-tuned printer back in Lake Placid).

Fully printed, attached to one of the patient's sockets. Notice how the hook feature wraps almost 270°, allowing for size adjustment by bending it outward.

Cleaned up and coated in a rubber sealant — to decrease porosity and provide a nice finish.

Mounted for testing. It deforms nicely when you put weight on it.

Looks like both a futuristic mushroom and a LEGO® minifigure hand — sleek and functional.

After fabricating the device, we shipped it to the patient. She loved having gym hand that finally worked, not to mention its rapid development cycle and low cost.